Table Of Contents

Recommended Sealing Methods

Air Duct Sealing is essential for improving energy efficiency and indoor air quality. For this purpose, several methods are available, each with its unique advantages. Mastic sealant is a popular choice due to its durability and flexibility, providing a robust barrier against air leaks. It can easily be applied to a variety of duct materials, ensuring a thorough seal. Duct tape, though widely used for its convenience, may not provide the long-term effectiveness desired. Its adhesive can degrade over time, which makes it less reliable than other sealing options.

Foam sealants are another alternative, known for their ease of application. They expand upon use, filling gaps and cracks effectively. This method is ideal for irregular surfaces where traditional sealing might fall short. Regardless of the sealing method chosen, proper preparation of the duct surfaces is critical for achieving optimal results. Preparing the area ensures that the sealant adheres well, further enhancing the efficiency of the air duct system.

Comparing Mastic, Tape, and Foam

When comparing mastic, tape, and foam for air duct sealing, each material presents its own advantages and considerations. Mastic, for example, offers excellent adhesion and durability, making it a preferred choice for long-lasting seals. It can be applied easily to various surfaces and fills gaps efficiently. However, mastic can require more time to dry and may be messier to work with compared to other sealing options.

Tape is often seen as a quick and convenient solution for air duct sealing. It provides immediate benefits with easy application and can be used for minor leaks. However, not all tapes are created equal; specialized duct tape specifically designed for high temperatures and air flow is essential. Foam, on the other hand, is versatile and can provide insulation as well as a seal, making it suitable for larger gaps. Each method has its place depending on the nature of the duct system and the type of leaks present.

Professional vs. DIY Duct Sealing

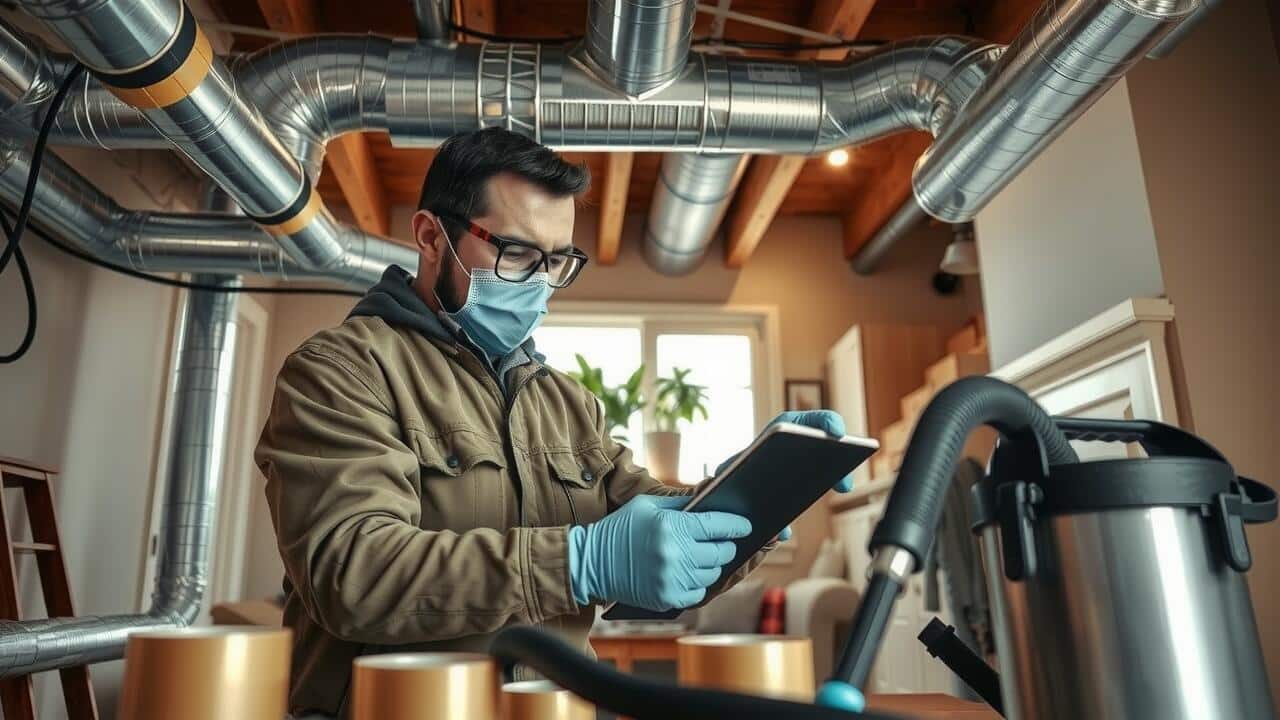

When considering air duct sealing, one must weigh the benefits of professional services against the efforts of a DIY approach. Professionals typically bring expertise, specialized tools, and experience in identifying problem areas that may not be visible to the untrained eye. Their thorough inspections and knowledge of local building codes ensure that the sealing is performed to high standards. This can lead to greater energy efficiency and longer-lasting results.

On the other hand, DIY air duct sealing can be a cost-effective option for homeowners willing to invest the time and effort. With readily available materials and detailed guides, individuals might successfully tackle minor leaks and gaps themselves. However, inexperienced sealing can lead to incomplete fixes, wasted materials, or even damage to the ducts. Assessing the complexity of the duct system and personal capabilities can aid in deciding which route to take.

When to Hire an Expert

Determining when to hire an expert for air duct sealing depends on a few key factors. If you notice significant air leaks or inconsistent heating and cooling in your home, it may be more effective to bring in a professional. Specialized tools and experience allow experts to identify hidden leaks that are difficult to detect, improving overall system efficiency.

Another situation that calls for expert assistance is when your ducts are old, damaged, or have never been sealed properly. Professionals can assess the condition of the ductwork and recommend the best sealing method, ensuring the longevity of the system. Hiring an expert also provides peace of mind, as they can handle complex issues that may arise during the sealing process.

Maintenance Tips for Sealed Ducts

Regular maintenance of sealed air ducts can prolong their efficiency and effectiveness. Inspecting the ductwork for any visible gaps or damage should be done periodically. Even the best sealing materials can degrade over time due to temperature fluctuations or external factors. Ensure that any visible wear is addressed promptly to prevent air leaks that can lead to energy loss.

Cleaning the air ducts is equally important. Dust and debris can accumulate inside, obstructing airflow and reducing system efficiency. A thorough cleaning helps maintain air quality and system performance. Additionally, consider scheduling professional inspections every few years to ensure that the air duct sealing remains intact and effective.

Ensuring Long-lasting Seals

Proper maintenance is essential for ensuring long-lasting seals in air duct systems. Regularly inspecting the ductwork for any visible deterioration or wear can help identify potential issues before they escalate. Areas where seals may loosen, such as joints and corners, should be monitored closely. Cleaning ducts periodically reduces the accumulation of debris and allows for better airflow. This also prolongs the effectiveness of the sealing materials used.

Choosing high-quality sealing methods during the initial installation can significantly impact the longevity of the seals. For air duct sealing, using durable materials like mastic or specialized tape is crucial. These options provide robust protection against air leaks. Additionally, maintaining the right humidity levels in the home can minimize the risk of moisture-related damage to the ductwork, further contributing to the durability of the seals.

FAQS

What is the best method to seal air ducts?

The best method to seal air ducts often depends on the specific situation, but commonly recommended methods include using mastic sealant, metal tape, or foam sealant. Each has its own advantages, with mastic being ideal for larger gaps, tape for quick fixes, and foam for flexibility in application.

How do I know if my ducts need sealing?

Signs that your ducts may need sealing include uneven heating or cooling in your home, increased energy bills, noticeable dust accumulation, and strange noises coming from your ductwork. An inspection by a professional can also reveal leaks.

Can I seal air ducts myself?

Yes, duct sealing can be a DIY project, especially for small repairs. However, if you encounter extensive damage or are unsure about the process, hiring a professional is recommended to ensure proper sealing and avoid further complications.

How often should I check my duct seals?

It is advisable to check your duct seals every few years, or if you notice any significant changes in your HVAC system’s performance. Regular maintenance can help extend the life of the seals.

What materials are best for sealing ductwork?

Mastic sealant, metal tape, and foam sealant are among the best materials for sealing ductwork. Mastic is durable and provides a strong bond, metal tape is easy to apply and effective for small gaps, while foam can fill irregular spaces effectively.